Scientists from the Massachusetts Institute of Technology (MIT) have developed lab-grown wood cells that could form the basis of a new, more sustainable 3D printable biomaterial.

By cultivating plant-based tissues like cultured meat, the researchers have been able to tune their morphology, and eliminate the wasteful harvesting that’s usually required to get wood. While the team’s research remains at an early stage, they believe that in future, it could be deployed as a means of 3D printing eco-friendly furniture, or producing synthetic woods that ease the growing deforestation crisis.

“We dedicate a lot of resources to growing whole plants, when all we use really is a very small portion of the plant,” Ashley Beckwith, the study’s lead author told the BBC, “so somehow we needed to figure out a more strategic way to reproduce materials that isn’t so reliant on the land.”

Replacing wood within production

Compared to fossil fuels, wood and other plant-based materials are often lauded for their renewability, and as a result, they’re regularly used to manufacture consumer goods as well as for energy generation. However, our over-reliance on lumber has increasingly led to large-scale deforestation, which could have lasting consequences for the environment.

Essentially, the way wood is grown and collected hasn’t changed for centuries, in that whole plants are cultivated, before the useful bits are harvested, and the rest is burned as natural waste. This approach results in much of the tree being discarded, and when the costs of land, fertilizer and transport are taken into account, it’s also rather expensive.

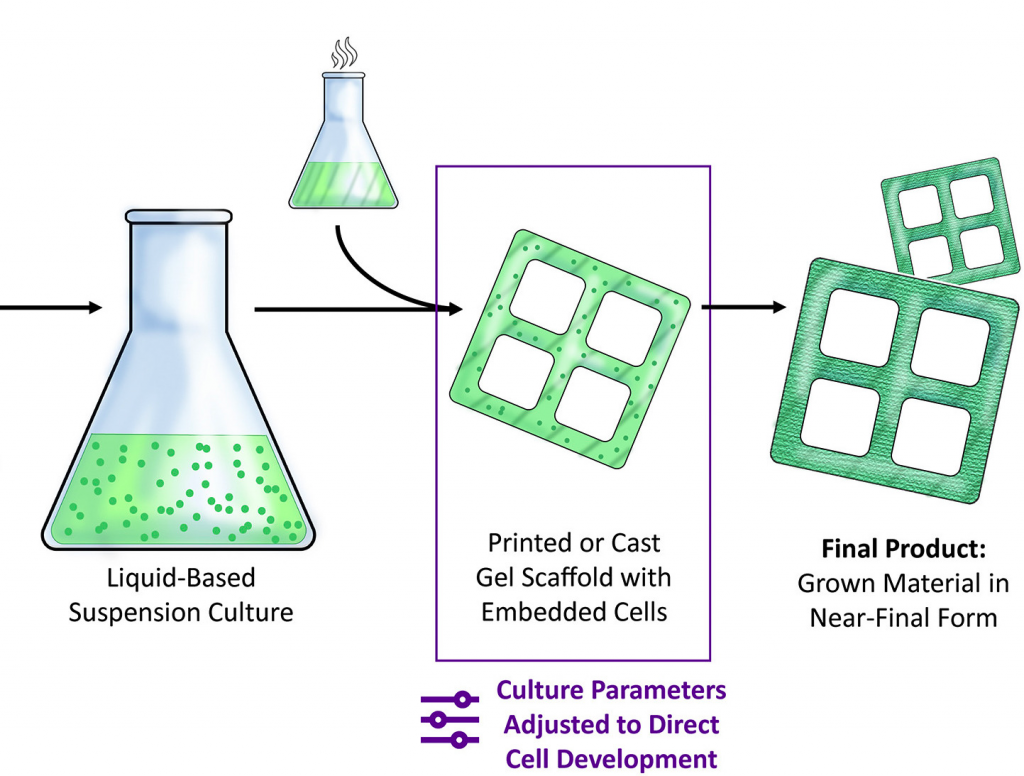

By contrast, lab-grown materials hold the potential to alleviate agricultural pressures, as they can be grown to specification, removing the need to discard unwanted pieces. Elsewhere, as part of a practice known as ‘micropropagation,’ small plant samples are grown into seedlings en-masse and redistributed, but the method is highly-selective, and often only used to save the rarest of species.

If applied to the growth of wood on a broader scale, however, micropropagation could have a much wider impact, dramatically reducing the time it takes to cultivate plant-based materials. By combining these approaches, the MIT team have therefore developed a novel biomaterial with tunable properties, and attempted to 3D print it into scalable complex structures.

Growing a novel biomaterial

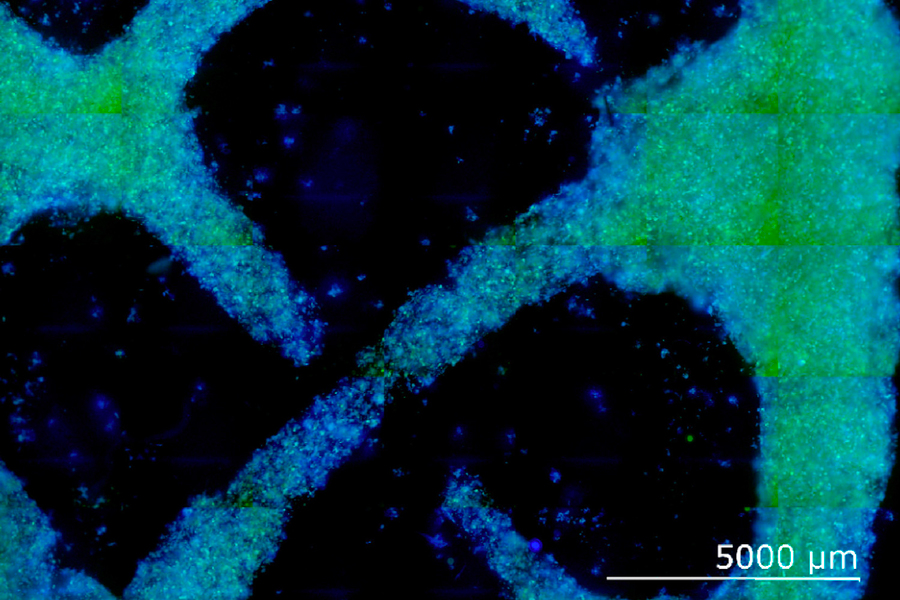

For testing purposes, the scientists extracted live cells from the well-studied Zinnia elegans plant species, cultured them using nutrients, and suspended them within a gel scaffold. In doing so, the team allowed the plant cells to grow into the scaffold, without needing sunlight or soil, and while only producing harvestable elements.

During cell growth, the researchers were able to tweak their hormone concentration, pH levels, density and overall function, ensuring that they yielded a biomaterial with optimal properties. After considerable tinkering, the team managed to align the cells, allowing them to develop a secondary lignin-reinforced wall, and effectively turn into a wood-based gel.

Once their new material was ready, the scientists used a combined 3D bioprinting and injection molding-based approach, to fabricate a series of thin tree-shaped test structures. While the printed objects exhibited a high cell viability of more than 70% over ten days, they also featured a low level of mechanical strength, which would currently limit their use within load-bearing structures such as furniture.

Consequently, the MIT team view their research as more of a proof-of-concept, that demonstrates the feasibility of growing wood more efficiently than current agricultural methods allow. With further R&D around culturing parameters, the researchers maintain that in future, their approach could yet yield various other 3D printed household products, which cause little or no damage to the natural world.

“I don’t know that I would grow a fully assembled table, because it’s not a very good use of space, but it has potential,” concluded Beckwith. “It’s a great vision, and people have really picked up on the concept, so I’m hoping that we generate some more interest, and get more people involved to make this really happen.”

Bio-based printing materials

As the race to head-off global warming heats up, scientists are now developing synthetic biomaterials as a more sustainable alternative to natural feedstocks.

Researchers at the University of Freiburg have taken a different approach to the MIT team, and created a novel wood-based 3D printing material of their own. Using compounded cellulose balls, the German team produced a biosynthetic polymer, that could be deployed within light construction or industrial applications.

Similarly, as part of the EU-backed NOVUM project, researchers are currently 3D printing cellulose-based components for use within the automotive, marine or electrical insulation industries. Overall, the program aims to drive greater global resource efficiency, as a means of both tackling climate change, and building a more circular economy.

In more experimental research, scientists at the German Federal Institute for Materials Research and Testing, are attempting to 3D print termite refuse into eco-friendly structures. While the novel biomaterial initially exhibited low mechanical strength, it was also capable of being binder jetted without polymeric additives.

The researchers’ findings are detailed in their paper titled “Tunable plant-based materials via in vitro cell culture using a Zinnia elegans model,” and was co-authored by Ashley L. Beckwith, Jeffrey T. Borenstein and Luis F. Velásquez-García.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows one of the researchers’ 3D bioprinted cultures with lignified cells. Image via the Journal of Cleaner Production.